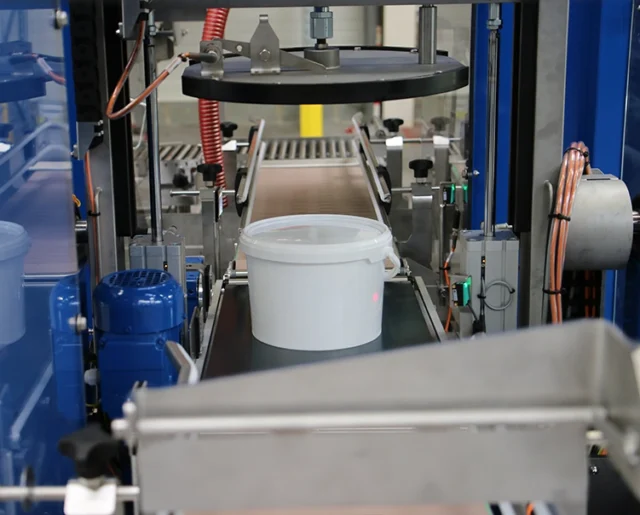

Precision Meets Speed

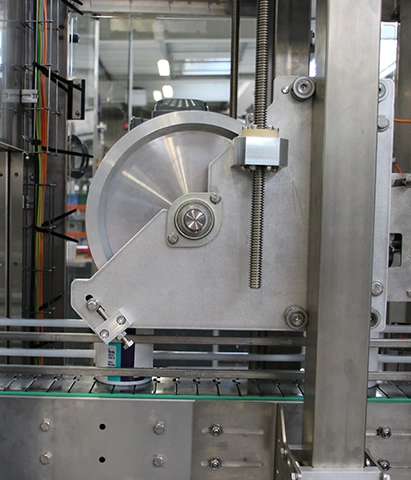

PACK’R develops capping machines engineered for the most challenging environments, where process stability and risk control are essential. Our systems deliver precise torque control, outstanding mechanical repeatability, and complete compatibility with corrosive, explosive, or variable-viscosity fluids.

All PACK’R capping machines meet international standards including ATEX, ExProof, IECEx, and UL certifications.

With installations running continuously for over 20 years, PACK’R is the trusted choice for manufacturers seeking reliable, safe, and high-performance capping solutions for even the most complex applications.