IFF Boosts Productivity with our Flavors & Fragrances Filling Machine

High-precision net-weight filling solution for sensitive and foamy liquid products

IFF – International Flavors & Fragrances Inc. is a global leader in the creation and innovation of flavors, fragrances, and specialty ingredients. The company partners with customers across the food and beverage, home care, personal care, and health and wellness industries to develop sensory experiences that enhance everyday products. With a strong focus on science, creativity, and sustainability, IFF combines advanced research capabilities with deep consumer insights to deliver solutions that meet evolving market needs worldwide.

Customer Production Process

The IFF Cedar Rapids facility is a biotechnology plant dedicated to enzymatic production for Animal Nutrition, Grain Processing, Household & Personal Care, and Food & Beverage industries.

The production process includes fermentation, purification, formulation, and final packaging. Finished products leave the plant as granular products or liquid forms packaged in tanker trucks, IBCs, drums, pails, or jerrycans.

Many of these liquids are highly concentrated or foamy, requiring precise dosing, controlled flow, and a reliable Flavor & Fragrance filling machine.

Challenges

Historically

- Outdated jerrycan filling line

- Very low productivity

- Output limited to 1 jerrycan every 2 minutes

- Hygiene and performance limitations

Initial Requirements

- Sanitary design for sensitive products

- Significant productivity increase

- High level of automation

- Integration within the existing plant layout

- Reliable handling of foamy liquids

PACK’R Filling Solution

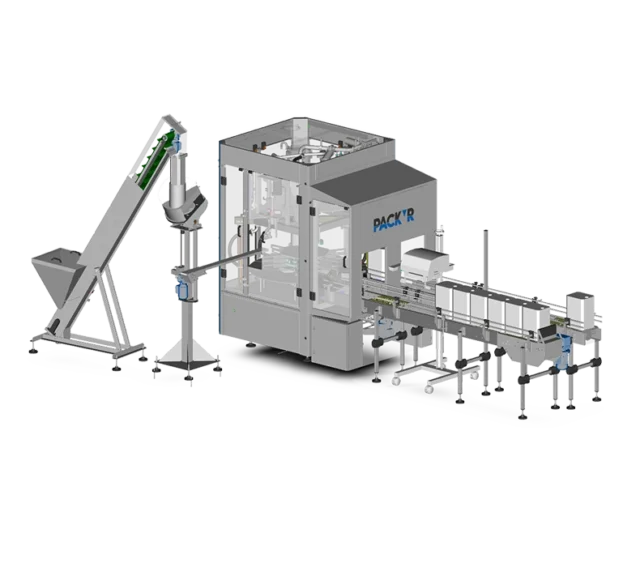

PULSA-S – Flavors & Fragrances Filling Machine

PACK’R recommended the PULSA-S, a high-performance automatic net-weight filling machine designed for sensitive industries such as flavors, fragrances, and biotechnology.

The standard configuration perfectly matched IFF’s technical requirements, with no need for custom development. The PULSA-S was also the only solution compact enough to fit into the restricted production layout.

Prior to installation, PACK’R’s test laboratory validated the machine using IFF product samples. Tests confirmed reliable handling of foaming behavior, viscosity variations, and concentrated liquids while maintaining excellent weight accuracy.

Technologies & Key Features

- Net-weight filling technology for maximum dosing accuracy

- Design adapted to sensitive liquids

- Anti-foaming filling technology

- Compact and space-optimized design

- Fully automated operation with intuitive interface

- Adjustable tooling for multiple jerrycan sizes

- Optimized filling to prevent waste and spray

- High-accuracy brushless capping system

- Stainless steel tank with infeed valves

- Level control for uninterrupted filling

Results

×8 productivity increase From 1 jerrycan every 2 minutes to 4 jerrycans per minute

BEFORE

Outdated filler, low output, hygiene constraints

AFTER

Compact, high-speed, fully automated filling solution

Key Improvements on the filling process

- Fully compliant sanitary design

- Smooth and reliable production

- Minimal maintenance requirements

- Adapted to three jerrycan formats

- Reliable filling of foamy liquids

Looking for a Flavor & Fragrance Filling Machine?

Contact PACK’R to design an automatic filling and packaging solution tailored to your production needs.