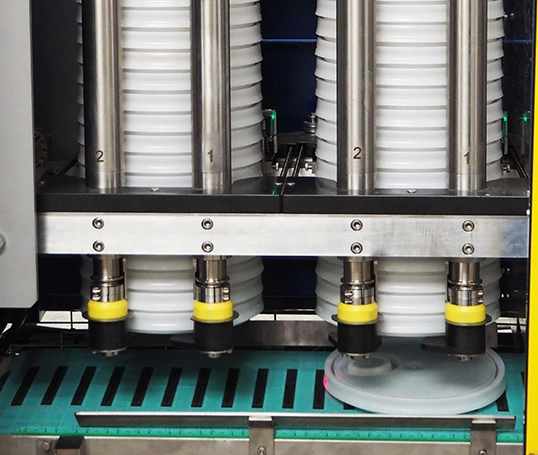

BOTTOM LID DENESTER

Automatic Bottom Lid Denesting System

Compact and efficient lid denesting system designed for smooth integration with can filling and capping machines.

Description:

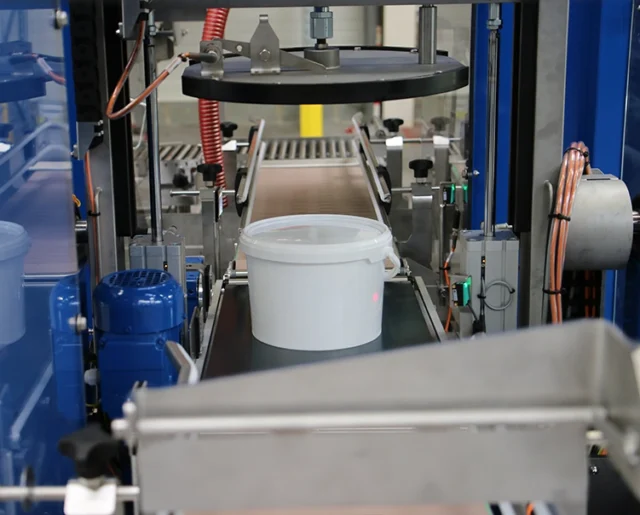

The Lid Denester automatically separates and feeds lids from the bottom of the stack onto the lid conveyor.

Available with 2, 4, or 6 stations, it offers high-speed operation of up to 7,200 lids per hour.

The system ensures continuous production, as operators can reload stacks during operation without downtime.

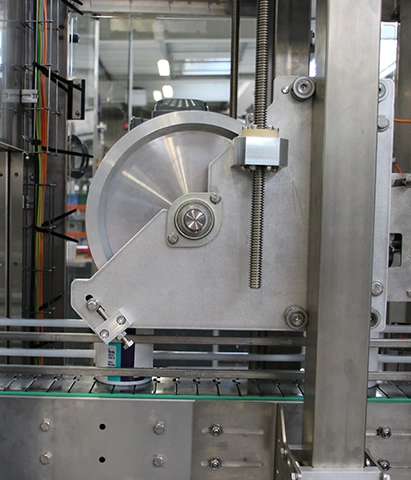

With its ergonomic loading area, automatic denesting unit, and tool-free format changeover, the Lid Denester delivers flexibility, reliability, and ease of use in a compact design.

Contact Us

- 2, 4 or 6 denesting stations

- Automatic denesting unit

- Ergonomic loading station

- Tool-free format changeover

- Continuous operation without downtime

- 1.2 m lid storage per stack

- ExProof, ATEX, IECEx, UL and EC design