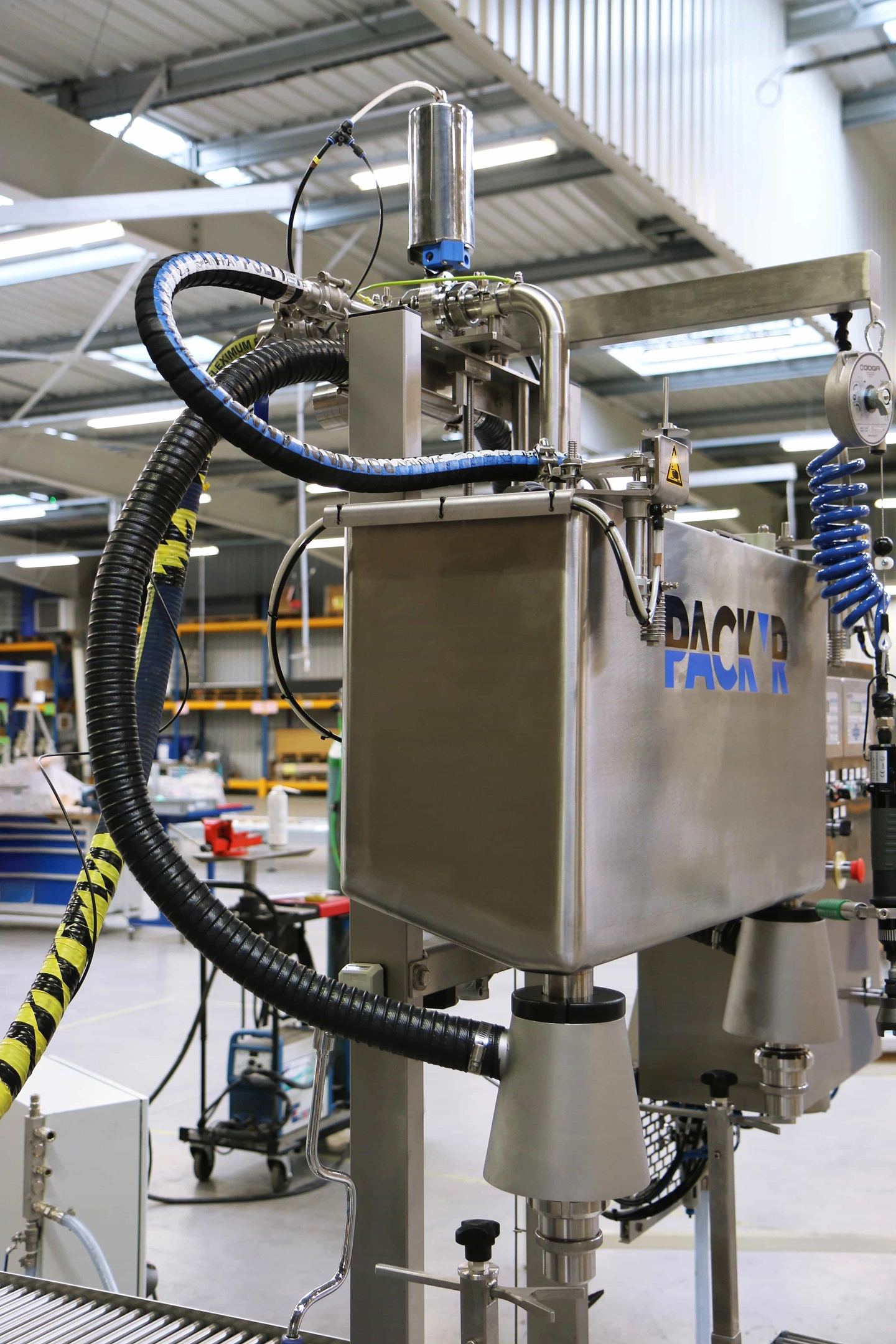

FLEXEO-S

Semi-Automatic Bottle Filling Machine

Semi-automatic bottle filling machine designed for both bottles and jerrycans. A reliable and flexible solution for small to medium production runs.

Description:

The semi-automatic bottle filling machine FLEXEO-S is a versatile and efficient solution designed to accurately fill bottles and jerrycans ranging from 3.5 fl. oz to 8 gallons. Engineered for medium-speed production lines, this machine offers up to 500 filling cycles per hour with high precision thanks to its advanced real-time weighing system. Ideal for a wide range of liquids, viscous products, and pastes, the FLEXEO-S ensures consistent fill levels while minimizing product waste.

Constructed with durable stainless steel or corrosion-resistant plastic components, this semi-automatic bottle filling machine is built for easy cleaning and rapid format changes without tools, making it perfect for small to medium batch runs. Its ergonomic design supports safe and efficient operation in industries such as chemical, petrochemical, food processing, paint, and vegetable oils.

Equipped with options like automatic capping (screw-on, push-on, or flexible spout closures), nitrogen dosing, fume extraction, and integration with motorized conveyors and labeling systems, the FLEXEO-S can be customized to meet specific production needs. Its ExProof compliance ensures safe operation in hazardous environments.

Download the FLEXEO-S Brochure

Contact Us

- Up to 500 CPH

- Net-weight filling technology

- Minimum product give-away with very high accuracy

- ExProof, ATEX, IECEx, UL and EC design

- Ergonomic and compact design

- Easy operation by one person

- Quick changeover

- Easy customisation with operations other than dosing

- Engineered for medium-speed production lines