Top Press Roller

Automatic Motorized Lid Closing System

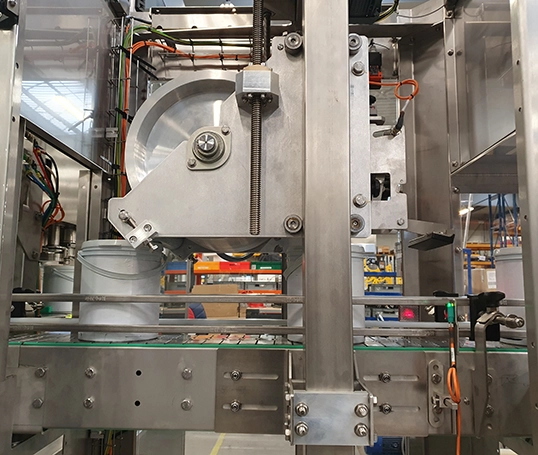

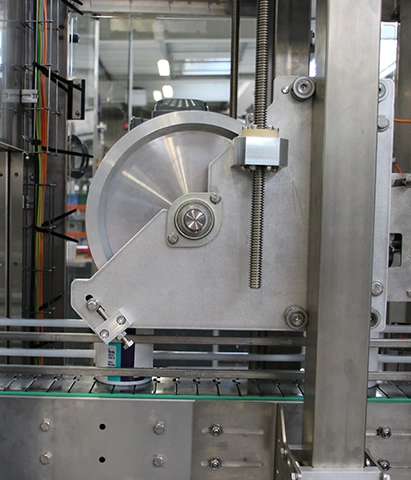

The Top Press Roller is a fully automatic lid closing machine designed for seamless integration after a filler and lid placing system. It ensures fast, precise, and consistent lid pressing for plastic or metal pails.

Description

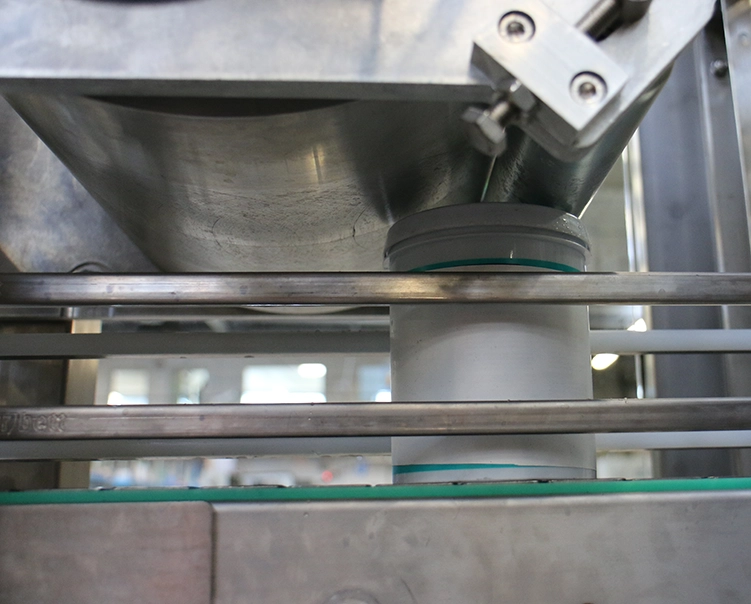

Installed directly after the filling machine and the lid placing unit, the Top Press Roller completes the closing cycle by securely pressing the lid onto the container. Once the filler has dosed the product and positioned the lid, the pail is conveyed to the Top Press Roller system, where a motorized height-adjustable roller ensures perfect lid sealing.

The machine is fully enclosed and equipped with safety sensors, easy access points, and an accumulation management system at the conveyor exit.

- Fully automatic lid pressing on pails

- Ideal for installation after fillers and lid placing systems

- Motorized top press roller with adjustable height

- Fully enclosed, safe, and easy to maintain

- Tool-free format changeover

- ExProof, ATEX, IECEx, UL and EC design