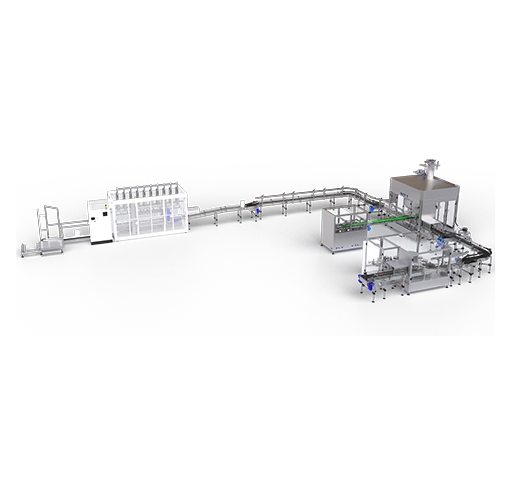

AUTOMATIC PAIL DENESTER

Description:

The Pail Denester PRPD is a key component of automated filling lines for conical pails. It handles pails up to 330 mm in diameter and 400 mm in height with high precision and consistency.

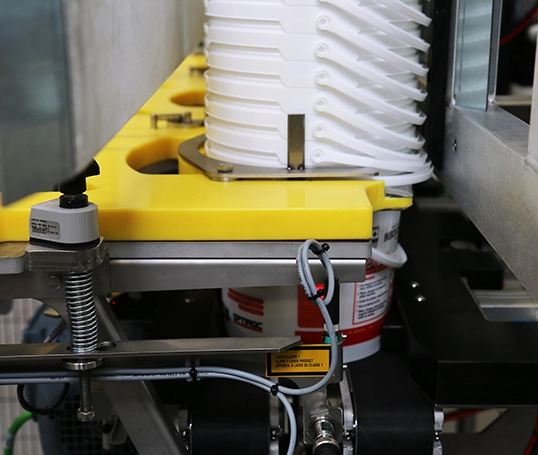

Operators manually load pail stacks onto a motorized conveyor from an ergonomic platform, ensuring comfortable and safe operation.

The system automatically transfers the stacks to the denesting unit, where pails are separated one by one and placed onto the discharge conveyor.

The Pail Denester is equipped with advanced automation features that allow it to synchronize perfectly with downstream fillers.

An intuitive touchscreen HMI provides full control of the machine, simplifying operation, format changes, and maintenance while minimizing downtime.

Contact Us

- 4, 6, 8, or 10 denesting stations

- Ergonomic loading station

- Automatic pile conveyor

- Automatic denesting unit

- Discharge conveyor

- Tool-free format changeover

- Touchscreen HMI for easy operation

- ExProof, ATEX, IECEx, UL and EC design