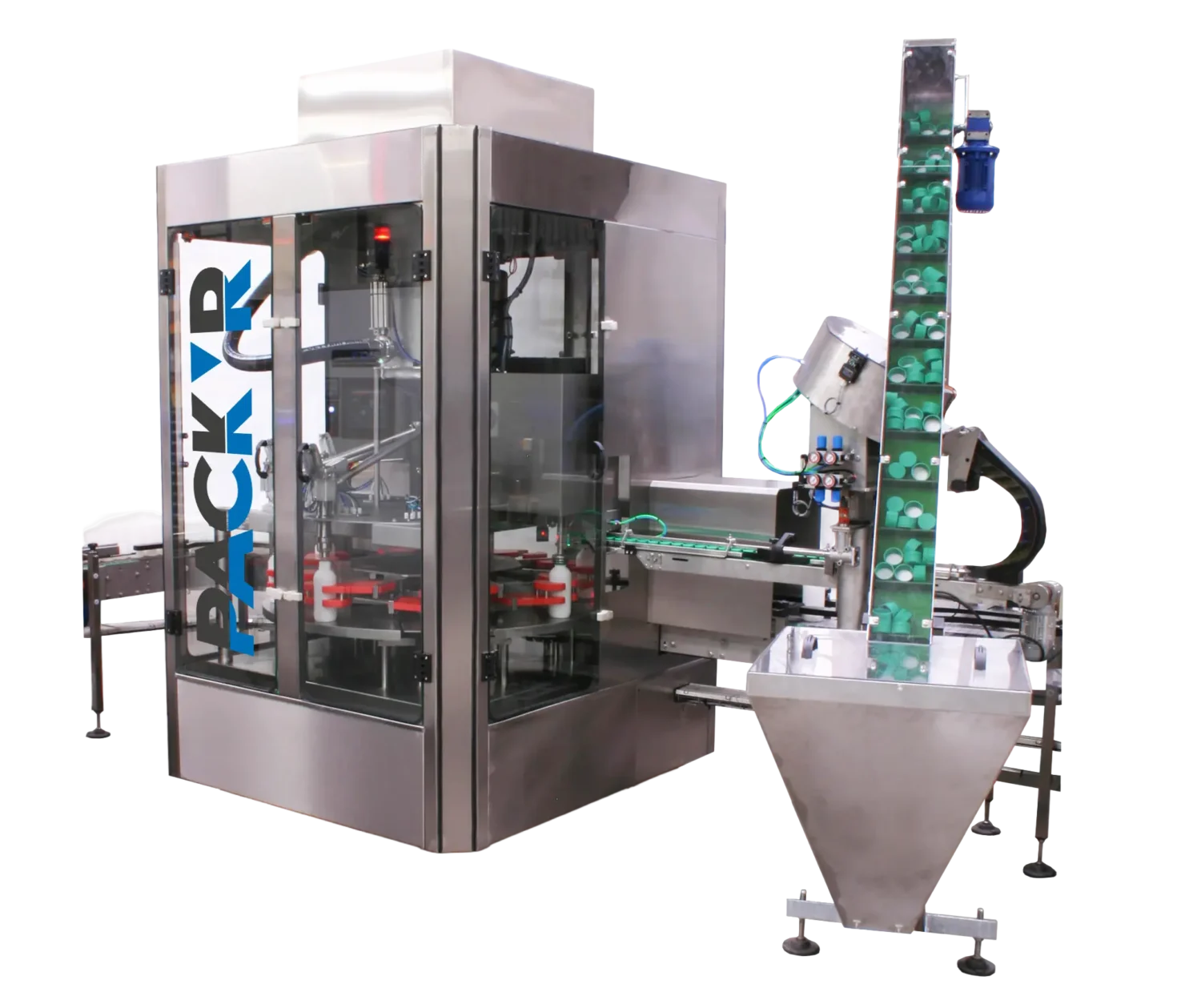

PULSA-S

Automatic Bottle Filling Machine

This automatic bottle filling machine is the best solution for compact, versatile and multitasks application with a maximum of 1,080 containers per hour.

Description:

Here at PACK’R, we assist small and large manufacturers around the world with our PULSA-S step-by-step filler capper equipment for their liquid products. Our equipment is designed to increase the speed and efficiency of operations while effortlessly integrating with existing production equipment for optimal operations.

The PULSA-S is a high-performance automatic bottle filling machine with capping system designed for a wide range of liquid products, whether foamy, viscous, or pasty. Engineered for flexibility, it handles a variety of container types including bottles and jerrycans making it ideal for multiple industries

Contact Us

- UP TO 1,080 CPH

- Net-weight filling technology

- Minimum product give-away with very high accuracy

- ExProof, ATEX, IECEx , UL design

- Small footprint

- Several layout configurations

- Easy customisation with operations other than dosing