REVO-B

Rotary Pail Filler Capper

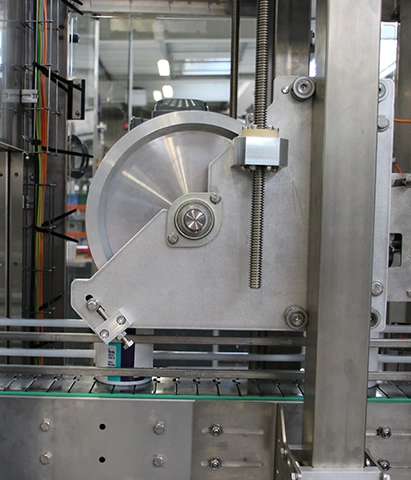

A fully automatic high-speed rotary filling machine for cans and pails. The highest accuracy with fast changeovers and high-efficiency cleaning.

Description:

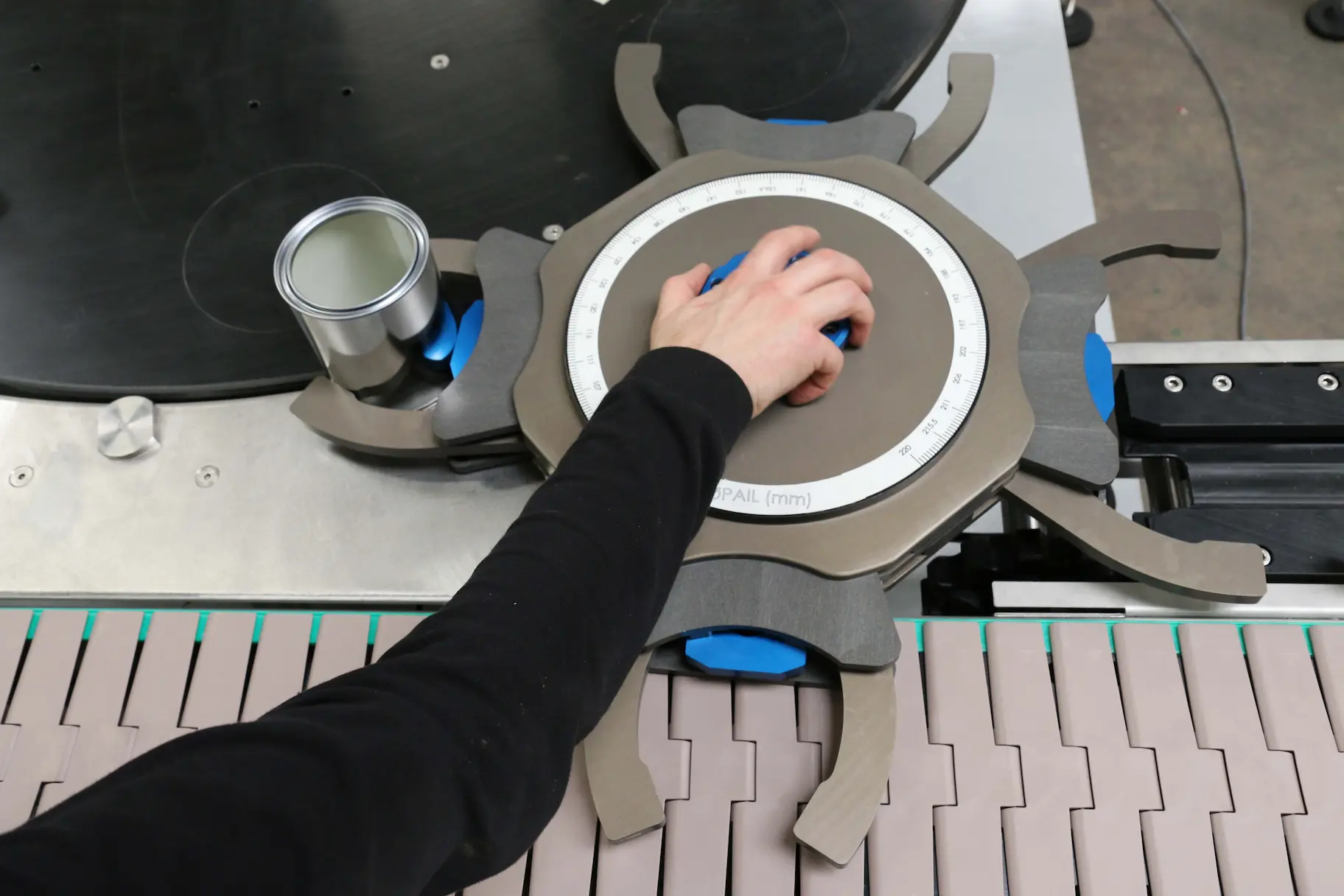

The REVO-B is part of our automatic filling machines for liquid products. Many types of products are compatible with this rotary pail filler capper. Products to fill can be foamy, viscous or pasty. This fully automatic filling machine has been developed to be compatible with cans and pails of different sizes with specific technologies such as our Smart Tooling with Click & Play for Quick Changeovers.

Filling accuracy is performed by a weighing scale (control, self-correction and statistics).

The container is moving continuously during different operations (filling, capping, etc…) giving high throughput capacities. The product can be fed by gravity or by the use of a pump.

Contact Us

- UP TO 36,000 CPH

- Net-weight filling technology

- Minimum product give-away with very high accuracy

- Easy customisation with operations other than dosing

- ExProof, ATEX, IECEx, UL and EC design

- Liquid can be foamy, viscous or pasty

- Format changeover without any tools

- Cleaning without stopping production