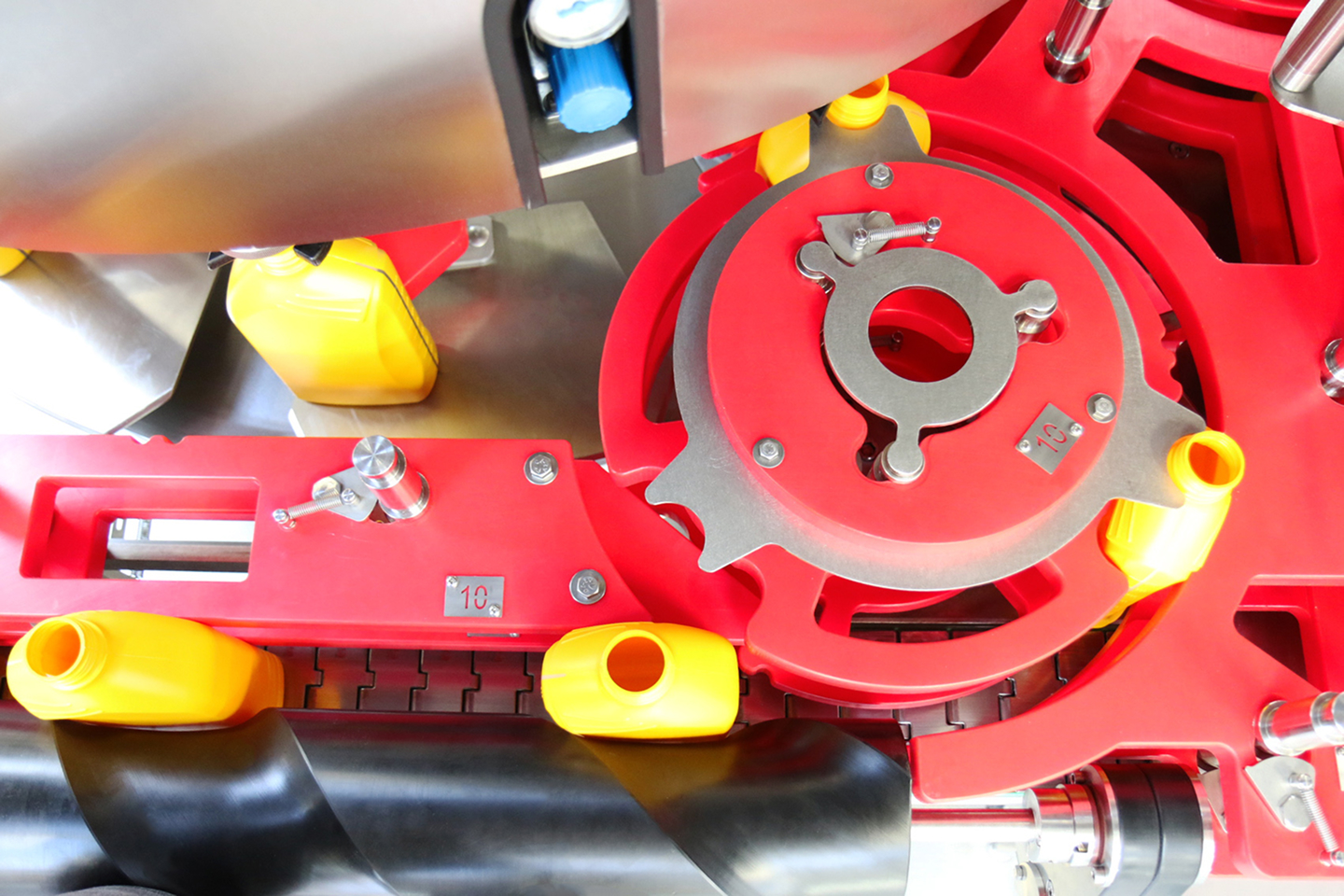

REVO-S

Rotary Bottle Filler and Capper

A fully automatic high-speed rotary filling machine with fast changeovers and high-efficiency cleaning.

Description:

The REVO-S is part of our automatic filling machines for liquid products. Many types of products are compatible with this high-speed filling machine. They can be foamy, viscous or pasty. This rotary bottle filler and capper fills also jerrycans of different sizes.

Filling accuracy is performed by a weighing scale (control, self-correction and statistics).

The container is moving continuously during different operations (filling, capping, etc…) enabling high throughput capacities. The product can be fed by gravity or by the use of a pump.

Contact Us

- UP TO 36,000 CPH

- Net-weight filling technology

- Minimum product give-away with very high accuracy

- Easy customisation with operations other than dosing

- ExProof, ATEX, IECEx, UL and EC design

- Liquid can be foamy, viscous or pasty

- Cleaning without stopping production