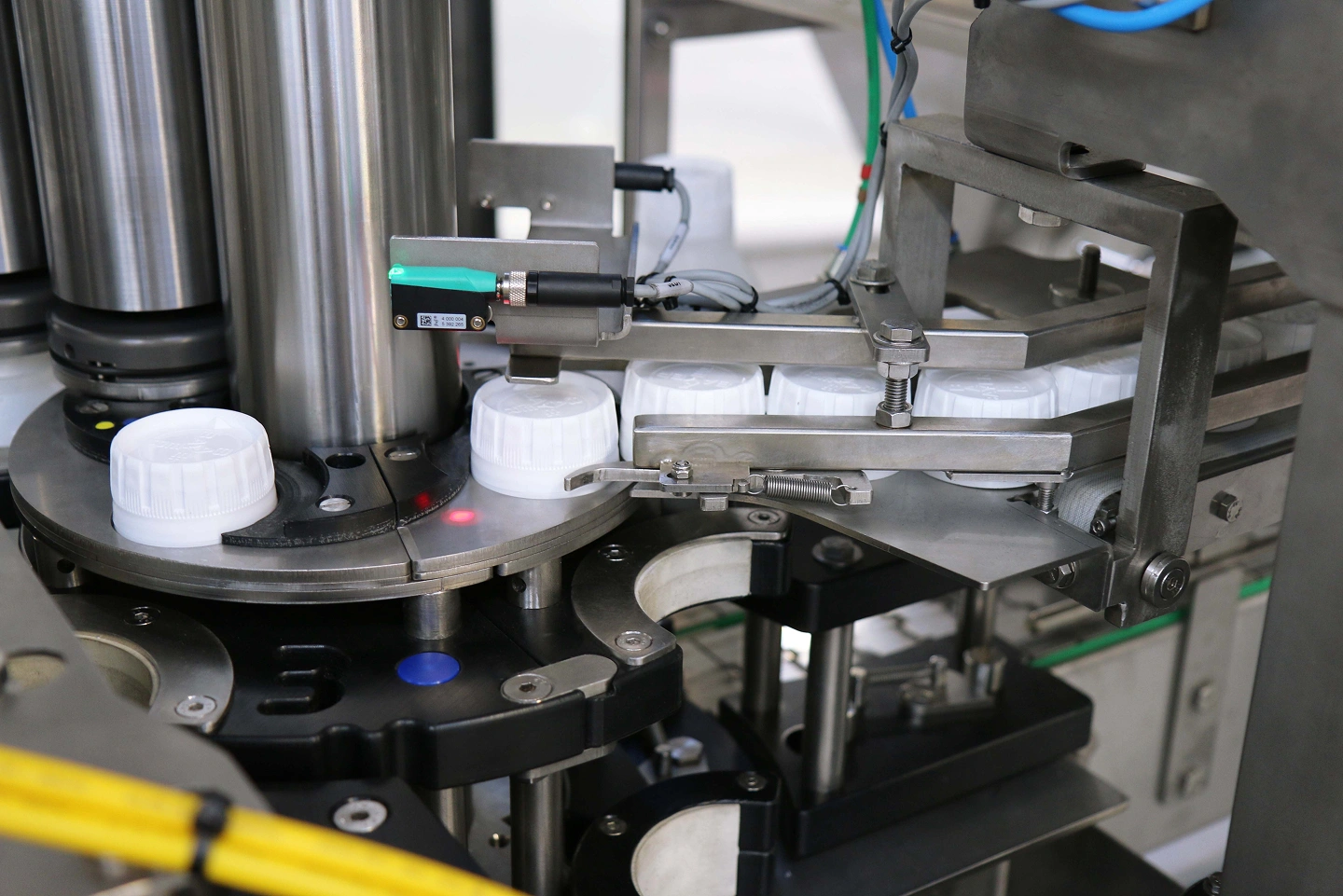

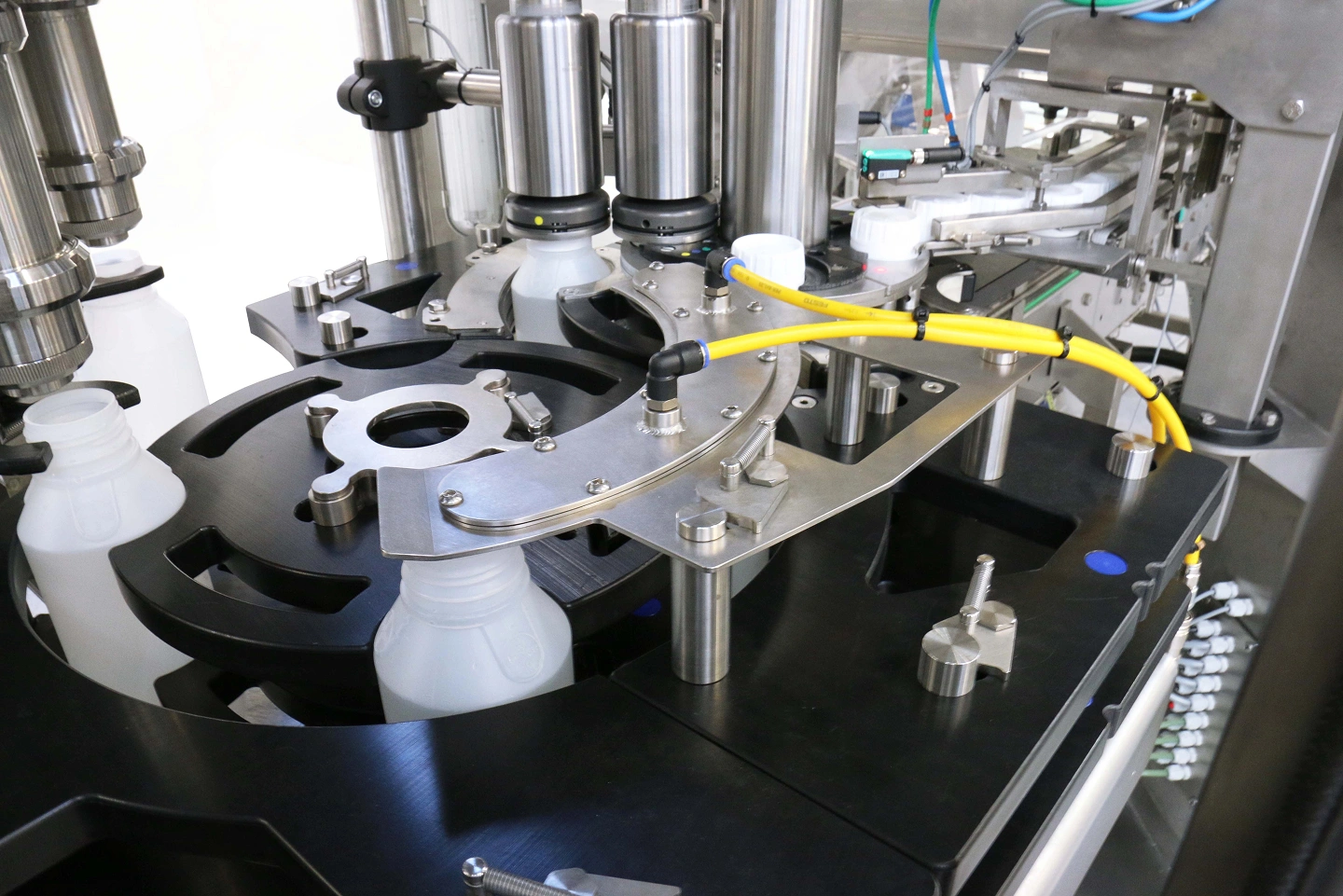

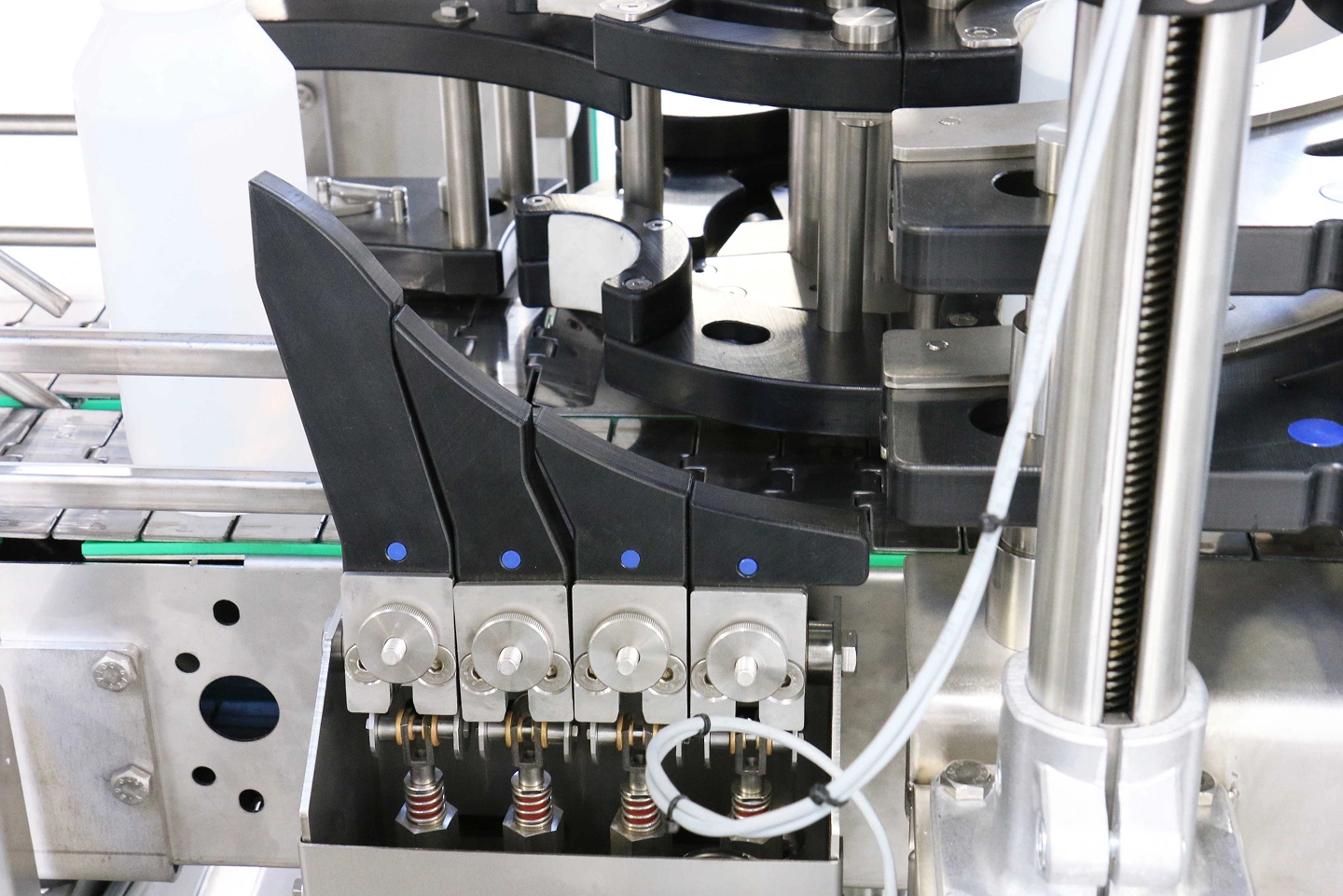

REVO-SC2

Compact Filler Capper

A high-speed filling and capping machine with compact design for small production areas.

Description:

PACK’R offers rotary compact filler capper to provide efficient filling and capping for all your liquid products.

Our compact liquid filling and capping system works with containers of 3,5 fl. oz to 5 gallons while providing output levels of up to 3,600 containers per hour.

This liquid filling machine can handle a range of cap sizes and configurations that includes screw caps, flexspouts, lids and push-on caps.

Download the REVO-S C2 Brochure

Contact Us

- UP TO 3,600 CPH

- Net-weight filling technology

- Minimum product give-away with very high accuracy

- Optimize footprint

- ExProof, ATEX, IECEx, UL and EC design

- Liquid can be foamy, viscous or pasty

- Clean In Place system

- Easy customisation with operations other than dosing