ROBOT CAPPER

Automatic Robotic Capping System

High-speed, fully automatic capping solution designed for maximum flexibility and precision across multiple container and cap types.

Description:

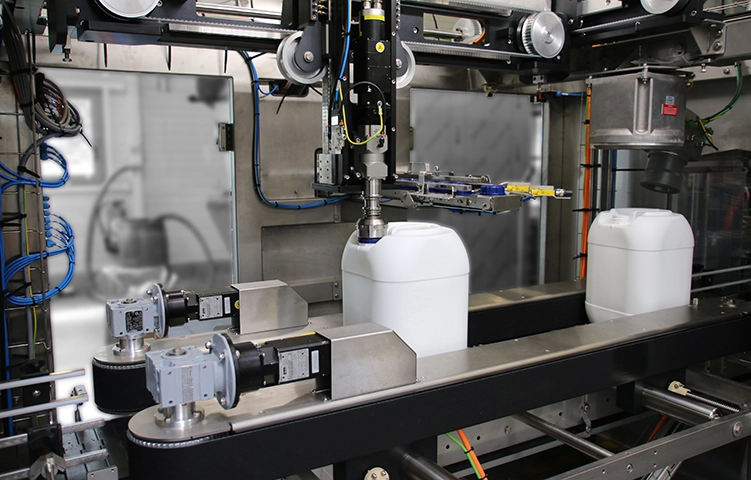

The Robot capper is part of our line equipment meant to be installed after a filling machine.

This machine is able to automatically process containers placed on a motorized conveyor. Accumulation and container pitch is manage by the robot capper. It is equipped with all necessary automation to increase operator efficiency such as missing cap detection, missing infeed container detection or jam detection at infeed & outfeed.

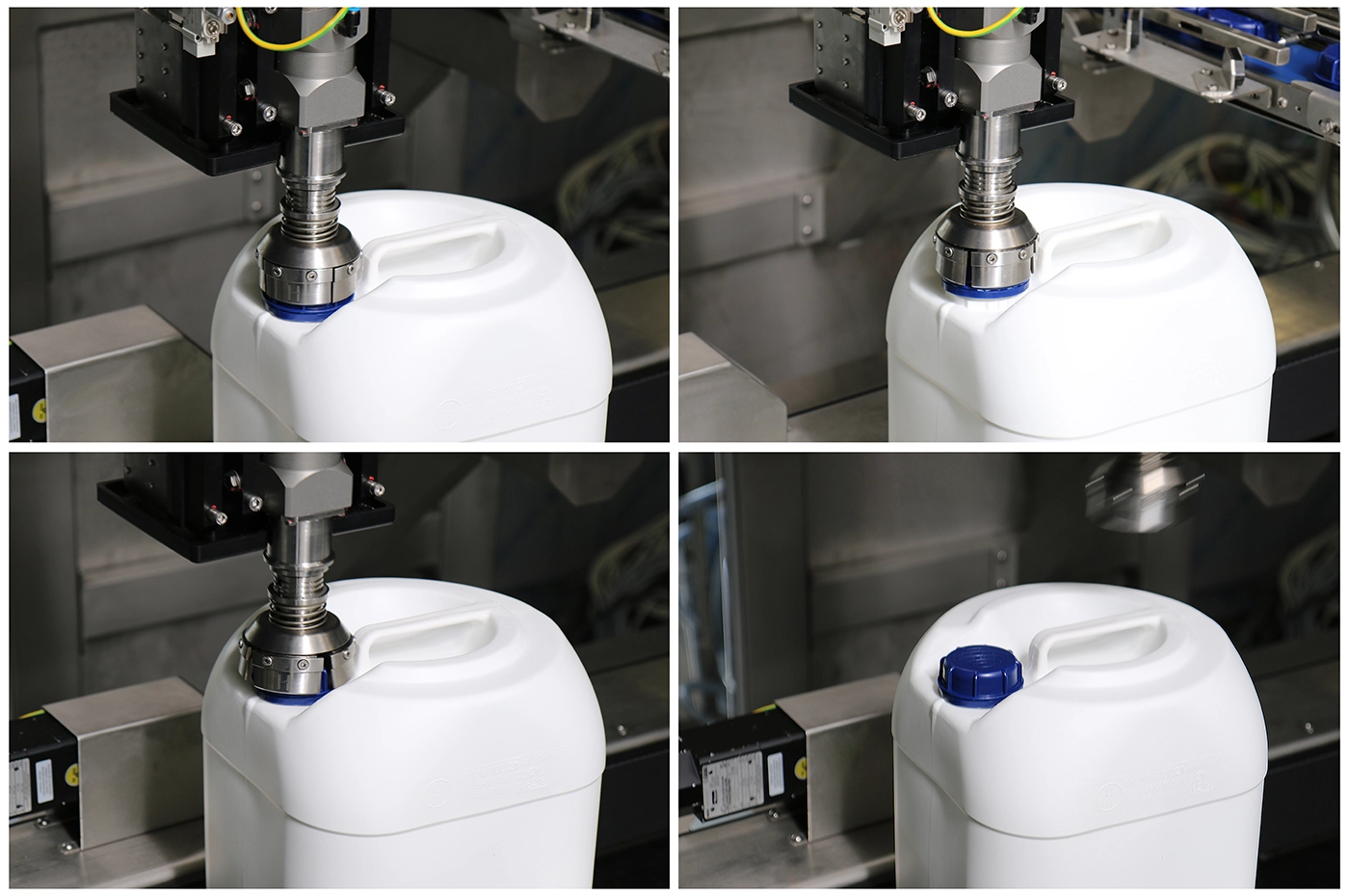

The revolution of this equipment resides in the changeover optimization. A Delta Robot is automatically picking caps on a conveyor belt to place them on dedicated pockets to supply the capping heads. Changing cap format (dimensions, color, type…) is only an automatic adjustment by recipe selection on the HMI.

Gantry system equipped with up to 5 brushless capping heads, our robot capper is able to deal with any kind of screw cap. Brushless motor allows operator to easily set up on HMI the torque to apply, detect wrongly capped containers and recover torque applied for each complete cycle.

Contact Us

- UP TO 3,300 CPH

- Up to 5 brushless capping heads (3–25 Nm)

- Delta Robot for automatic cap sorting and placement

- Automatic spacing and feeding system for containers on conveyor

- Tool-free format changeover

- Touchscreen HMI for control and monitoring

- ExProof, ATEX, IECEx, UL and EC design