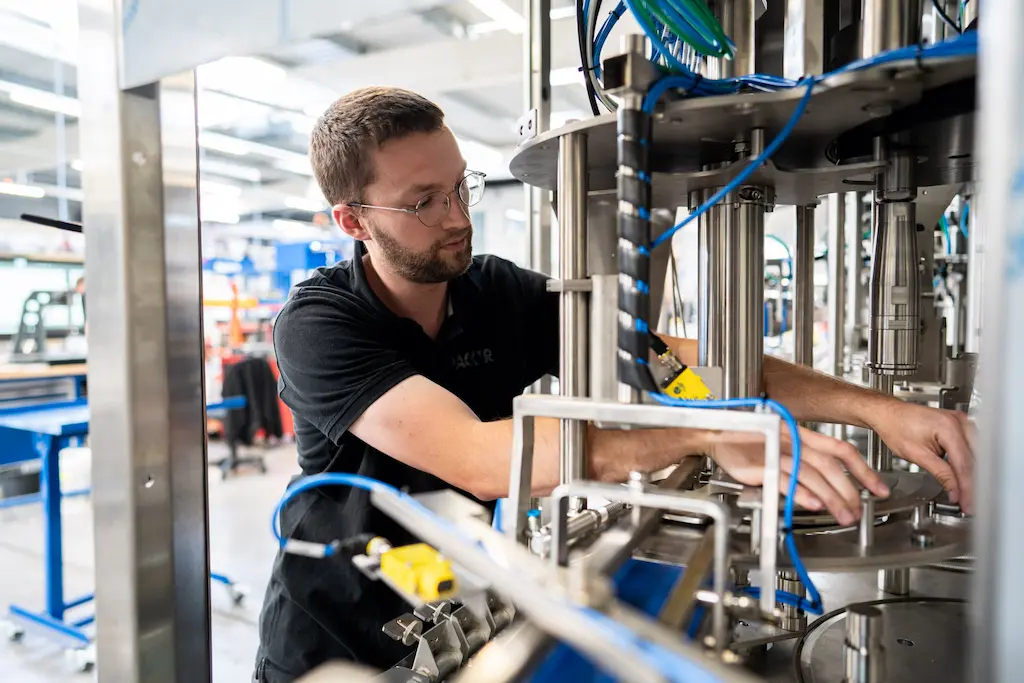

Quality Maintenance Services

We feature a number of packaging machine service offerings that can help your filling equipment maintain accurate, effective, high-quality operation, in areas like screwing quality, dosing precision and more.

Our services include regular diagnostic visits, periodic maintenance and preventive maintenance to maintain the efficiency of your equipment and the quality of your products (dosing precision, screwing quality).